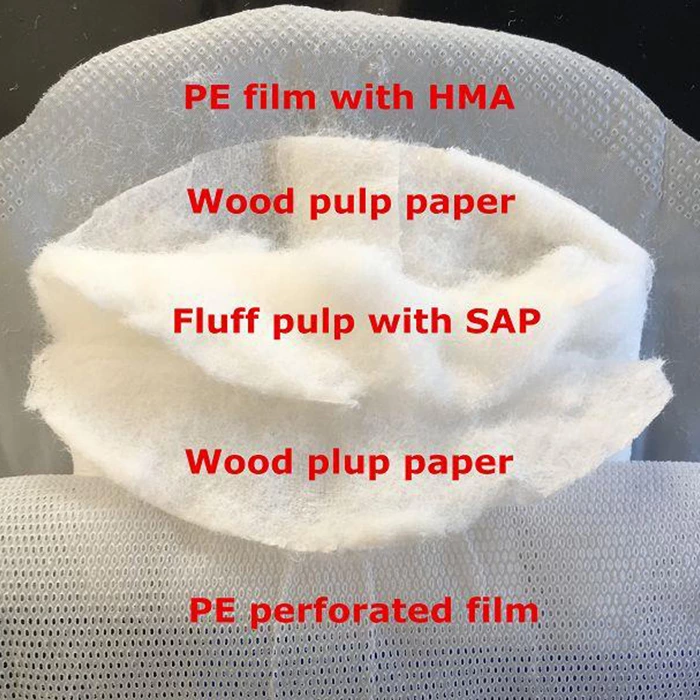

Fluff pulp is a high-performance absorbent material widely used in baby diapers, adult incontinence products, and sanitary napkins. We supply high-quality fluff pulp sourced from trusted fluff pulp manufacturers, including Domtar, ensuring consistent performance and safety.

Our diaper fluff pulp offers superior absorbency, fast liquid wicking, and excellent retention capacity, making it ideal for use with super absorbent polymers (SAP) in disposable hygiene products. We also provide untreated fluff pulp for customers who require custom processing or specific chemical-free applications.

👉 Request Free Sample | Download Technical Datasheet | Get a Quote