High-Performance Diaper Absorbent Core | SAP & Fluff Pulp Composite Solutions

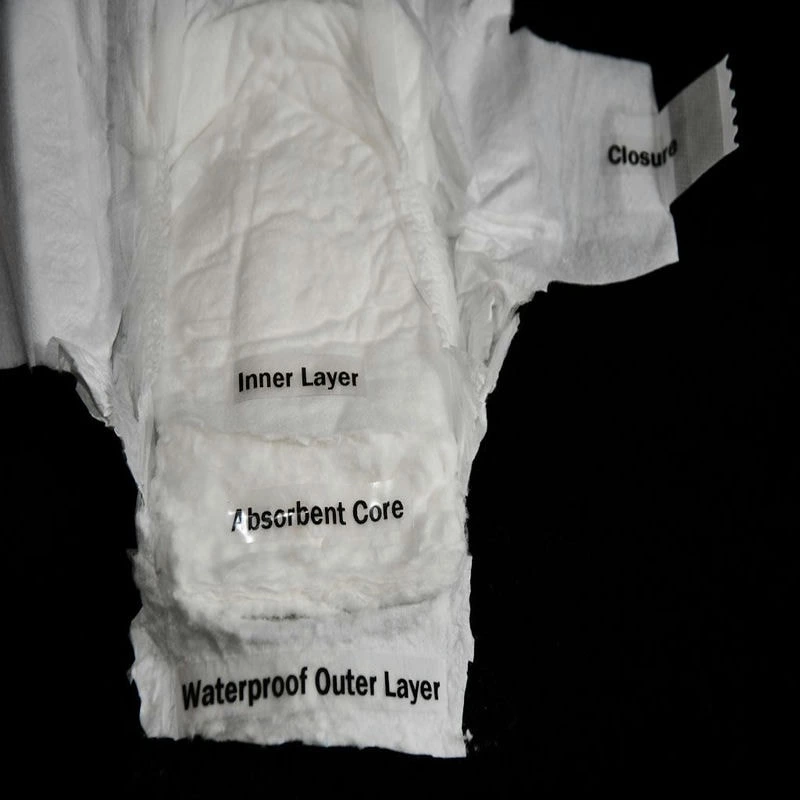

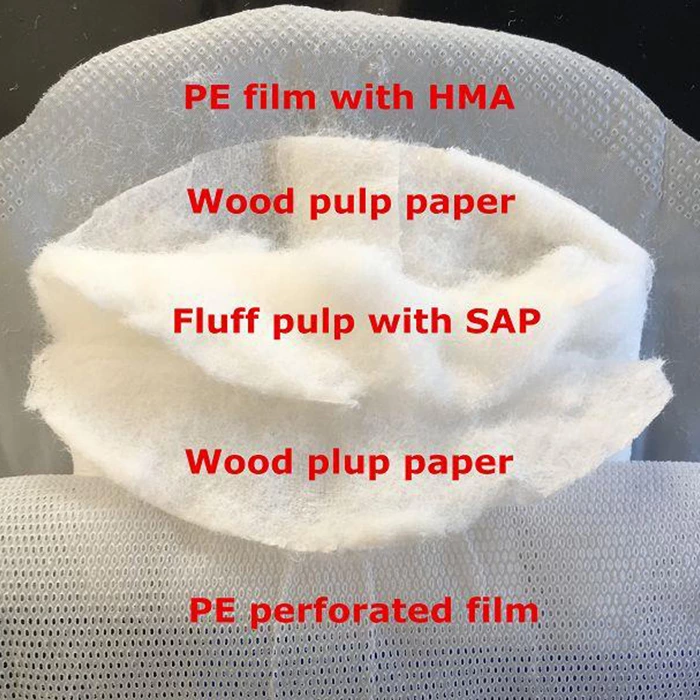

Our super absorbent core is designed for baby diapers, adult diapers, and feminine hygiene products, combining super absorbent polymer (SAP) and fluff pulp into a highly efficient absorption system.

With fast liquid intake, high retention capacity, low rewet performance, and customizable structures, our diaper absorbent core helps manufacturers achieve superior dryness, comfort, and product differentiation.

ISO 9001 & SGS certified. OEM/ODM supported. Free samples available.

[Get Free Samples] [Download Specification Sheet] [Request a Quote]