Super Absorbent Polymer (SAP) — Reliable Supply for Baby Diapers & Hygiene Products

Overview — SAP for Absorbent Hygiene

Super absorbent polymer (SAP) is the core diaper polymer used in modern disposable diaper manufacturing to achieve high liquid absorption, reliable retention, and effective leakage prevention.

As a critical diaper absorbent material, SAP plays a decisive role in diaper performance, comfort, and product differentiation for manufacturers.

This page provides a structured technical overview of diaper polymer, explains how super absorbent polymer functions in diaper absorbent systems, outlines key performance indicators, and offers practical guidance for SAP selection and sourcing.

What Is Diaper Polymer?

Diaper polymer refers to the polymer-based absorbent material used in the core of disposable diapers to absorb and retain liquid.

In modern disposable diaper design, super absorbent polymer (SAP) has become the standard diaper polymer, replacing traditional absorbent-only structures. SAP is engineered to retain absorbed liquid under pressure, a requirement that fibrous absorbent materials such as fluff pulp cannot meet independently.

As a result, SAP is an essential component in baby diapers, adult incontinence products, and other absorbent hygiene applications.

Super Absorbent Polymer (SAP): The Core Diaper Absorbent Material

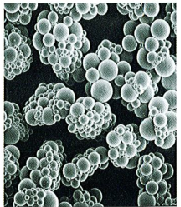

Super absorbent polymer (SAP) is a cross-linked hydrophilic polymer designed to absorb and retain large quantities of aqueous liquid.

Its three-dimensional polymer network enables rapid absorption and stable gel formation, even under mechanical stress.

In diaper manufacturing, SAP is typically blended with fluff pulp to form the absorbent core. This structure allows manufacturers to achieve:

-

High absorption capacity with reduced core thickness

-

Improved liquid distribution and retention

-

Enhanced comfort and flexibility

-

Effective leakage protection during movement and compression

Due to these advantages, SAP is widely recognized as the most effective diaper absorbent material in modern hygiene products.

Why Super Absorbent Polymer Is the Industry Standard Diaper Polymer

Super absorbent polymer has become the industry standard diaper polymer because it simultaneously fulfills three critical performance requirements:

-

Rapid liquid uptake to prevent surface wetness

-

High liquid retention under pressure during movement

-

Compatibility with thin and flexible diaper core designs

These requirements define modern disposable diaper performance. Without SAP, achieving high absorption would require significantly higher fiber volume, resulting in bulkier, less comfortable products.

How SAP Works in Diaper Absorbent Systems

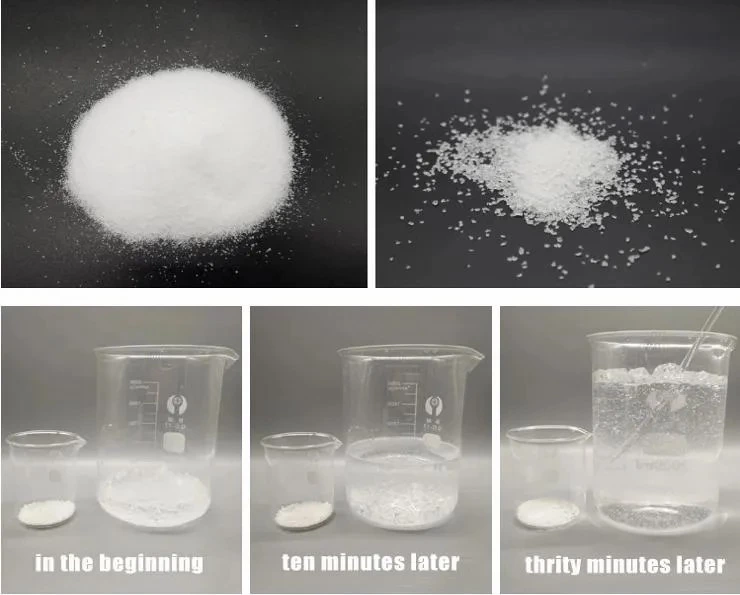

When liquid contacts the diaper core, SAP particles immediately begin absorbing moisture and swelling into a gel structure.

This gel formation locks liquid within the polymer network, preventing fluid migration and minimizing rewet during use.

Overall diaper performance is influenced not only by SAP quality, but also by how it is incorporated into the absorbent core. Factors such as particle size distribution, SAP concentration, and the balance between SAP and fluff pulp directly affect absorption speed, retention under pressure, and wearer comfort.

The ability of SAP to immobilize liquid after absorption is the primary reason modern diapers can remain thin while delivering high leakage protection.

Without SAP, increasing absorption capacity would require significantly higher fiber volume, resulting in bulkier and less comfortable diapers.

Global Super Absorbent Polymer (SAP) Market Overview

Industry market research consistently indicates that the global super absorbent polymer (SAP) market reached a value of approximately USD 11 billion in 2024 and is expected to experience steady growth over the next decade.

This expansion is primarily driven by increasing demand from baby diapers and adult hygiene products, which together represent the largest share of SAP consumption worldwide. Ongoing improvements in diaper performance standards and consumer expectations for comfort and leakage protection continue to support SAP demand.

From a regional perspective, the Asia-Pacific market plays a significant role in global SAP consumption, supported by population growth, rising hygiene awareness, and expanding diaper manufacturing capacity. At the same time, interest in sustainable and environmentally optimized absorbent materials is gradually increasing in markets with stricter regulatory requirements.

Key Brands & Supply Channels

As a trading company, we source SAP from reputable global manufacturers and authorized distributors to ensure traceability and stable quality. Typical brands and manufacturers we can source include:

- Sumitomo (high-performance hygiene SAP grades)

- BASF (HySorb® / SAVIVA® series — known for consistent performance)

- LG Chem (broad SAP portfolio for hygiene applications)

- Nippon Shokubai (proven SAP technologies and global capacity)

- San-Dia Polymers and other regional producers for cost-sensitive grades

Note: HC Industry does not claim exclusive manufacture rights; instead we manage procurement, quality control and export logistics with these recognized suppliers to give customers multiple sourcing options (brand consolidation, split shipments, or single-brand supply) according to budget and application.