Frequently Asked Questions (FAQ)

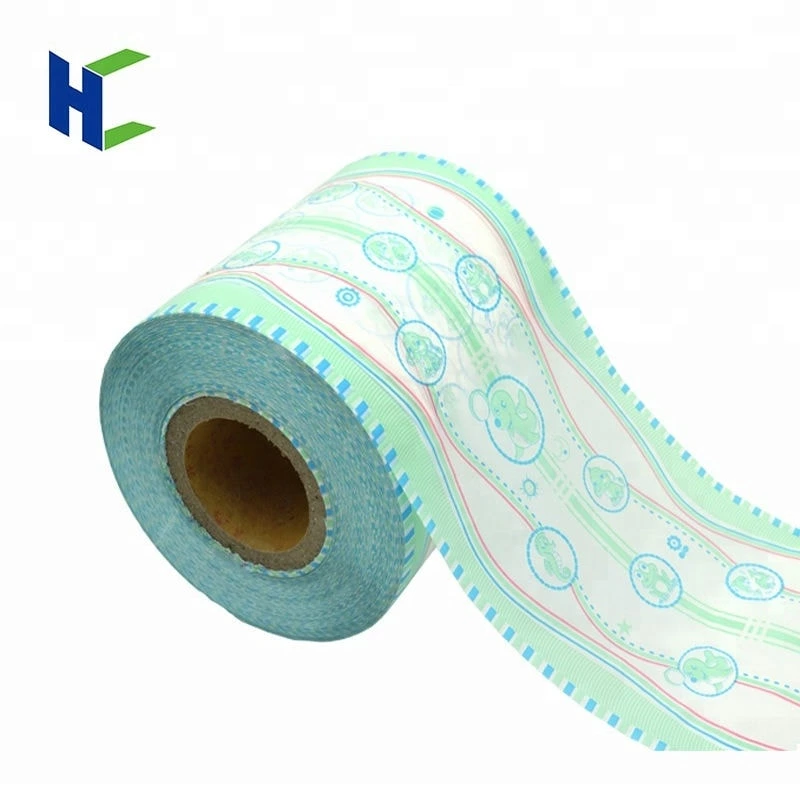

Q1: What is the difference between breathable and non-breathable PE film?

A1: Breathable PE film uses a microporous structure allowing air and vapor to pass through while still preventing liquid leakage — enhancing skin comfort and reducing diaper rash risk. Non-breathable film provides a solid waterproof barrier, ideal for high absorbency diapers or cost-effective products.

Q2: How do I choose the right thickness and weight for diaper backsheet?

A2: Diaper backsheet thickness and GSM depend on diaper type and target cost. For newborn/infant diapers, thinner breathable films with softer surface are preferred for comfort; for adult diapers or heavy-absorbency products, thicker, stronger non-breathable films ensure leakage prevention. Contact us with your diaper design and use-case to get a recommended specification.

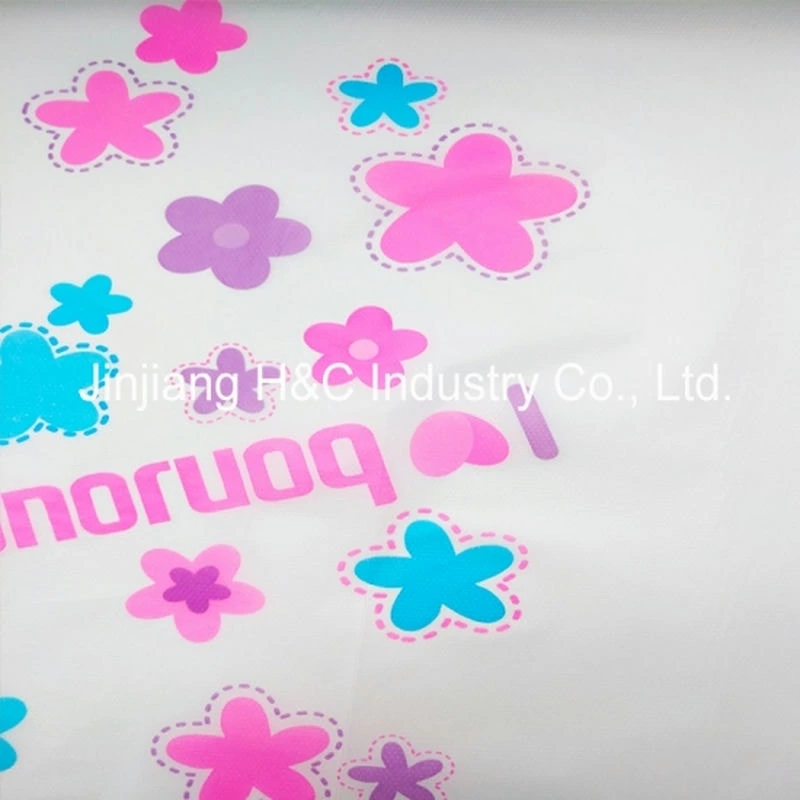

Q3: Can you print our brand logo or design patterns on the film?

A3: Yes. We support custom printing and embossing. Provide your artwork or request our design team for layout support. Printed film will undergo QC to ensure ink adhesion, readability, and waterproof integrity before shipping.

Q4: What is your minimum order quantity (MOQ), and lead time?

A4: MOQ depends on film type, thickness, printing, and customization. We support small MOQ for trial orders. Typical lead time is [2–6] weeks after sample confirmation. Contact us for precise quote based on your volume and specification.

Q5: Do you provide free samples for testing?

A5: Yes. We offer free sample rolls for quality, breathability, and printing testing. Simply submit your requirements through the “Get Free Samples” button — we’ll process your request promptly.